Center for Electric Vehicles

ELECTRIC MOBILITY LABORATORY

The Electric Mobility Laboratory is designed to support research, development, and hands-on learning in electric vehicle (EV) technologies. Equipped with testing and training equipment, the lab plays a vital role in fostering a deeper understanding of EV systems, aligning with the increasing demand for sustainable transportation solutions.

The primary focus of this laboratory is to facilitate experimentation, prototyping, and analysis of electric vehicle components, including electric motors, battery management systems (BMS), drivetrain assemblies, and control units. The lab is specifically geared towards enabling users to gain expertise in critical areas such as hub motor performance, cell-level battery diagnostics, electric vehicle assembly, battery pack design, and the integration of IoT features in EV systems.

This collection of equipment is carefully selected to cover a wide range of electric vehicle technologies, ensuring that users can engage in in-depth study and practical experimentation. The equipment available in the lab not only supports academic curricula but also promotes research initiatives focused on advancing electric vehicle technologies, with an emphasis on efficiency, safety, and sustainability.

Objectives & Opportunities:

- Hands-on Training & Research: Develop practical skills in EV assembly, battery management, and motor testing, while participating in cutting-edge research.

- Industry Collaboration & Innovation: Work on real-world projects, develop sustainable mobility solutions, and engage with industry experts.

- Skill Development & Career Growth: Obtain certifications in EV technologies, participate in internships, competitions, and startup initiatives to enhance employability and entrepreneurship.

The Electric Mobility Laboratory serves as a vital resource for students, providing them with practical training that bridges the gap between theory and real-world applications. By supporting experiments in motor testing, battery management, IoT integration, and EV assembly, the lab plays a key role in preparing students for careers in electric mobility and related fields.

| Name of the Equipment | Features | Applications |

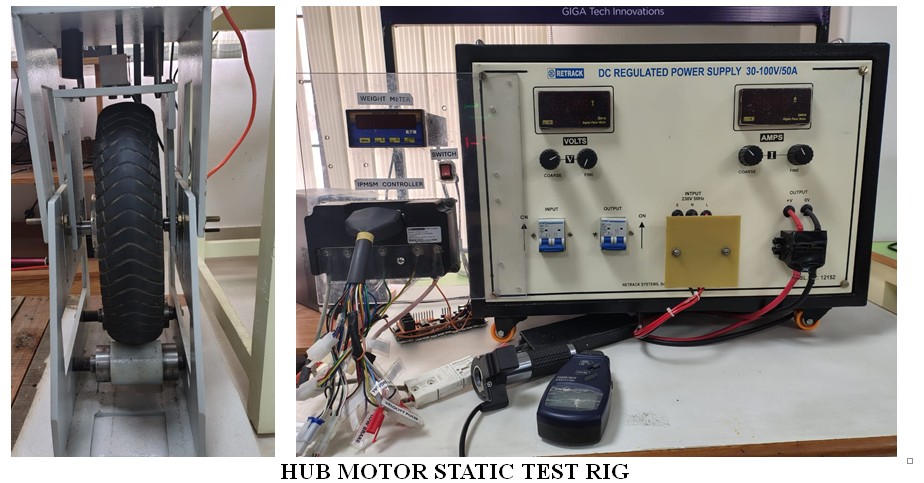

| Hub Motor Static Test Rig-1kW, 50 A, 100V |

|

|

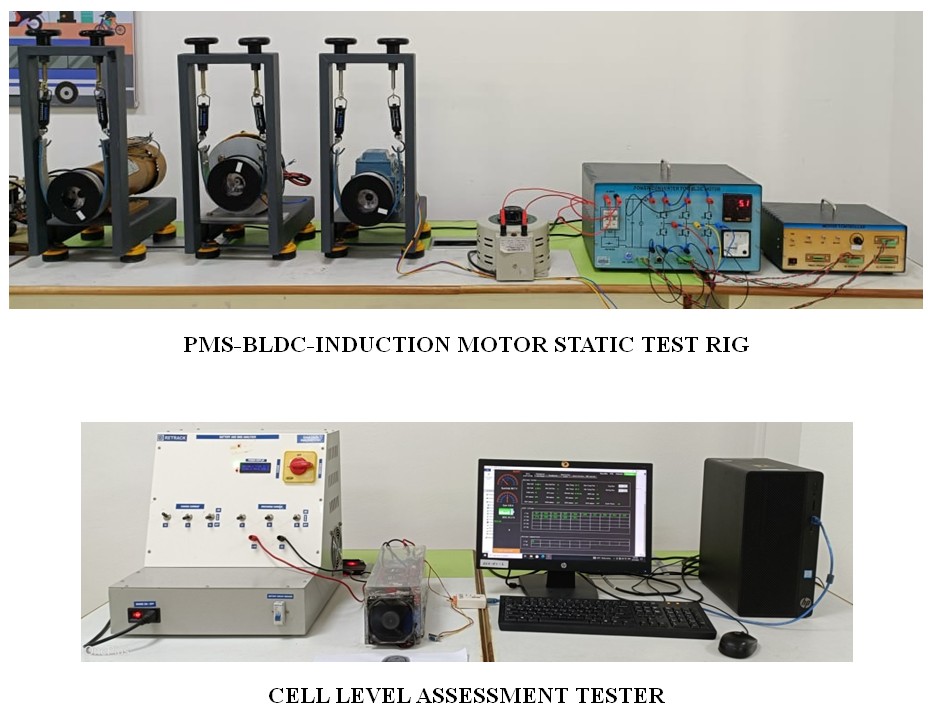

| PMS-BLDC-INDUCTION Motor Static Test Rig. |

|

|

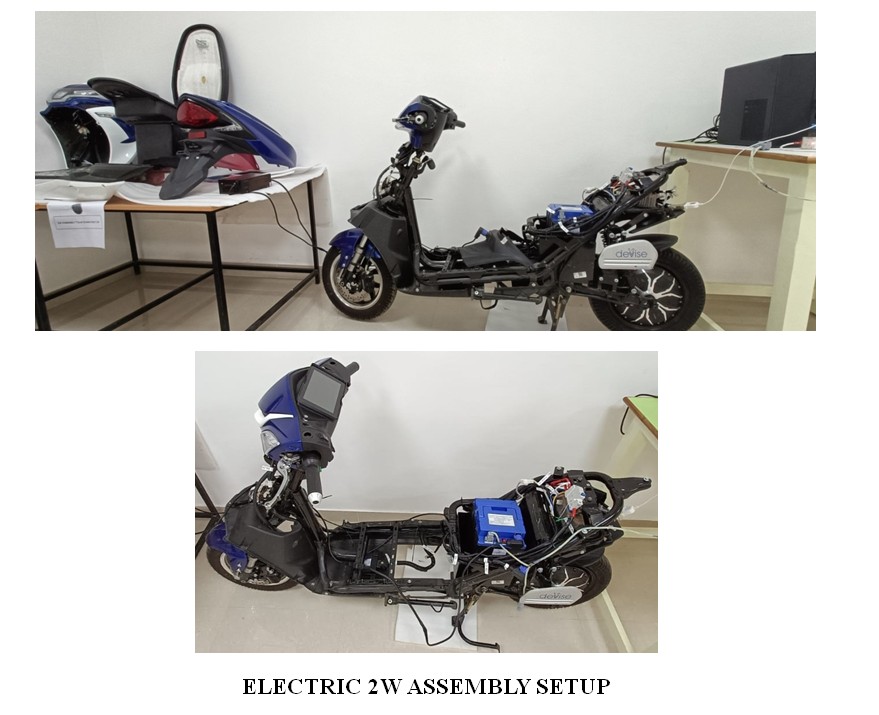

| Cell Level Assessment Tester |

|

|

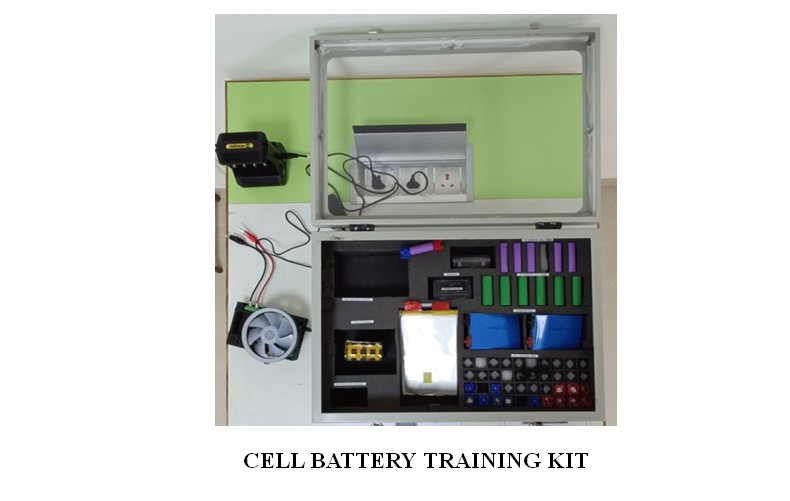

| Electric 2W Assembly Setup |

|

|

| Cell Battery Training Kit |

|

|

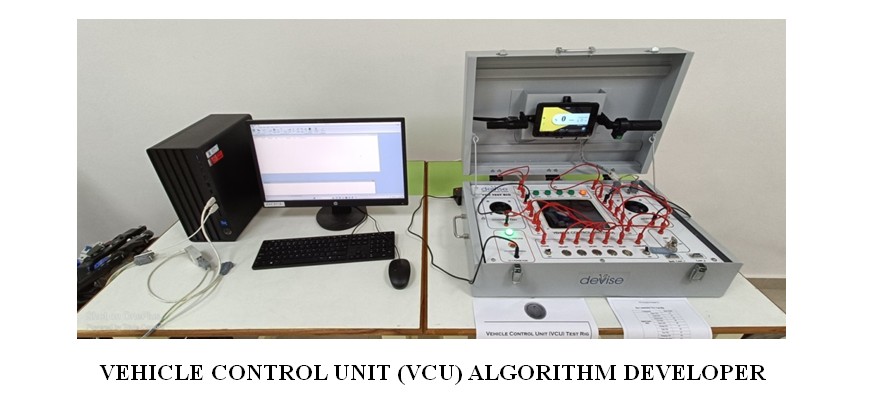

| Vehicle Control Unit (VCU) |

|

|

| Battery Pack Test Rig |

|

|

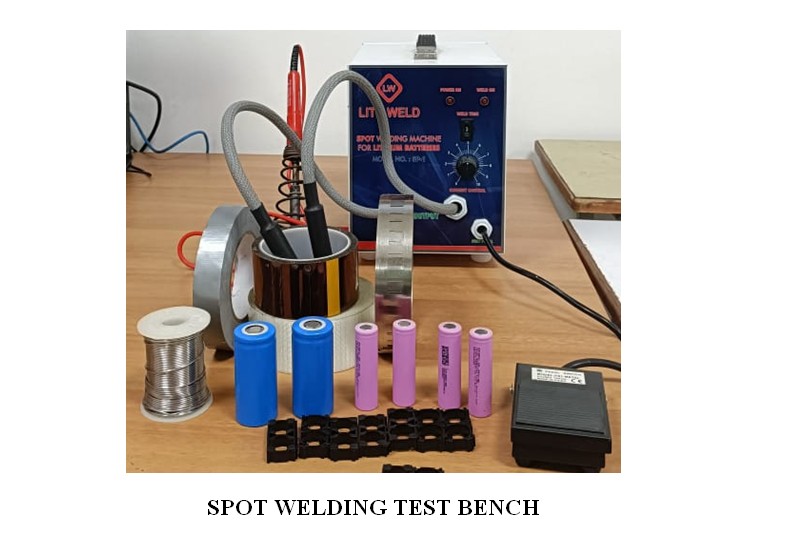

| Spot Welding Test Bench |

|

|

| Active cell balancer |

|

|

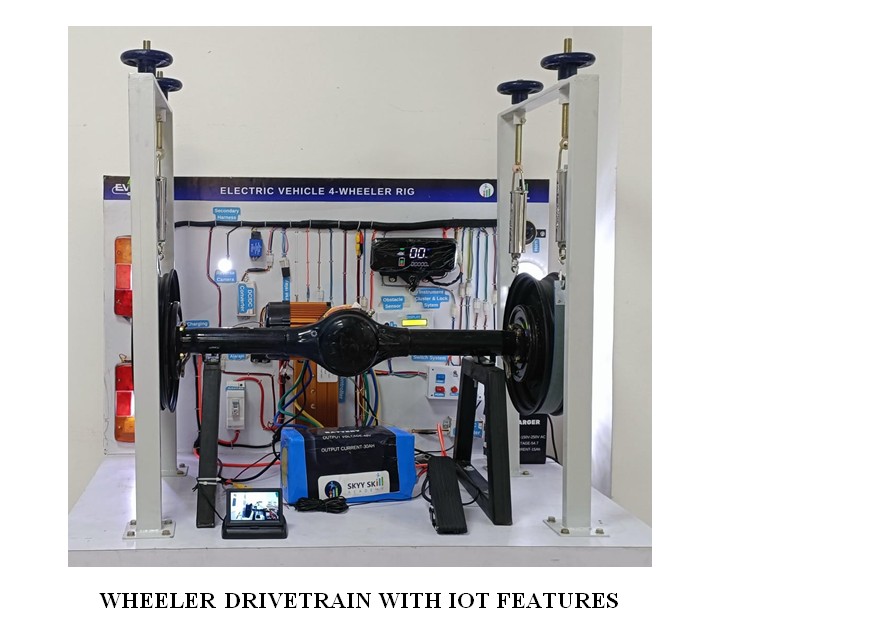

| 4-wheeler drivetrain with IOT feature and training Facility: Battery for Test rig 48V 15AH LIFEPO4 and SMPS Charger for LFP battery with BMS 48V 8Ah battery for the above test rigs |

|

|

| Battery Management Training Systems |

|

|